Brunswick Craftsmanship

Brunswick has been the market leader for billiards and game room furnishings since 1845 because we offer the industry’s largest selection of high quality product, backed by a lifetime warranty and supported locally by the best dealer network in the business.

Discover how the 12 Hidden Differences in Brunswick tables add up to better playability and greater value.

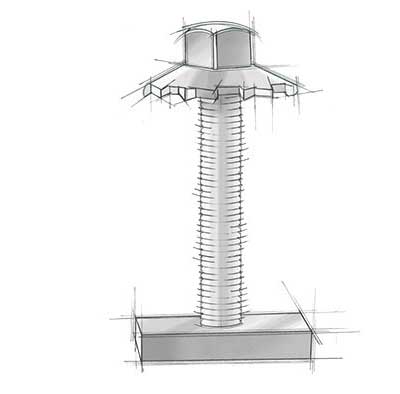

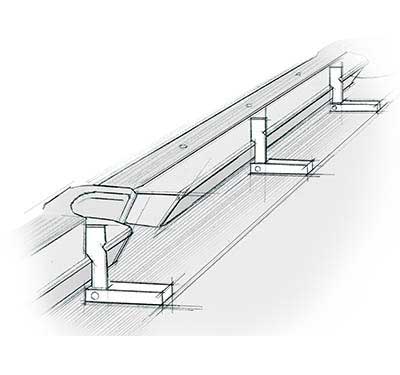

1. High Performance Nut Plate

Brunswick’s exclusive High Performance Nut Plate, which is used to attach the cushioned rails to the slate, allows for the ability to apply 70% more torque to each connection versus typical T-nut type hardware. The result is a solid, seamless transition between rail and slate for enhanced performance and playability.

2. Hardened Domed Washer

To maintain the integrity of the rail-to-slate connection long term, a hardened domed washer is utilized which provides constant tension between the rail and the slate, and prevents loosening over time. This domed washer grips the slate directly, preventing turning or sinking into wood like the competition.

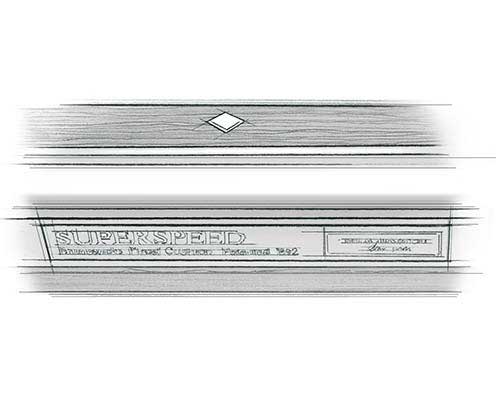

3. SuperSpeed® Cushion Rubber

Brunswick SuperSpeed cushions have been the standard in the industry for over 70 years and are used on all Brunswick branded tables. They are made to Brunswick’s exact specifications from a proprietary rubber formulation. This results in an exceptionally consistent rail on every Brunswick product. SuperSpeed cushion rubber incorporates a thin layer of cotton canvas vulcanized into the top and back surfaces of the cushion. This feature results in controlled ball penetration and greater accuracy in rebounding.

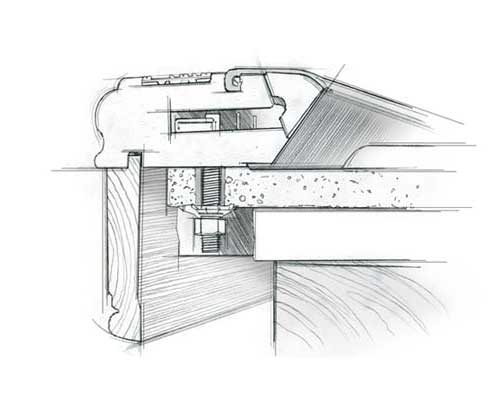

4. High Pressure Bonding

Precision is the name of the game, and cushion rubber bonding and placement are a critical element to the overall performance of a table. Brunswick achieves superior accuracy and consistency in its tables by using Brunswick- designed, automated, pneumatically controlled machines that bond the cushion rubber to the rails for a precision fit that doesn’t vary.

5. Accurate Nose Height

Banking and rebound accuracy rely on the nose height of the cushion rubber. Automated, pneumatically controlled machines ensure, through precise placement of the cushion rubber, that the nose height is consistent all around the table and meets the standard of 64% of a 2 1⁄4" diameter ball.

6. Solid Hardwood Rails

Brunswick rails are made of solid hardwood. The rails are machined to exacting standards and provide a solid foundation behind the cushion rubber to ensure exceptional accuracy and performance.

7. Machined Recessed Area

The rail has a recessed area machined into it where the rail cloth can be stapled securely, many times over. The area is recessed so the staples or cloth do not interfere in any way with the rail attachment to the slate.

8. Stable Joinery Construction

Brunswick utilizes fine furniture joinery techniques in the construction of all solid hardwood products. These joinery techniques, such as panels glued together with alternating grain patterns, create a stronger, more stable furniture construction that will last for generations.

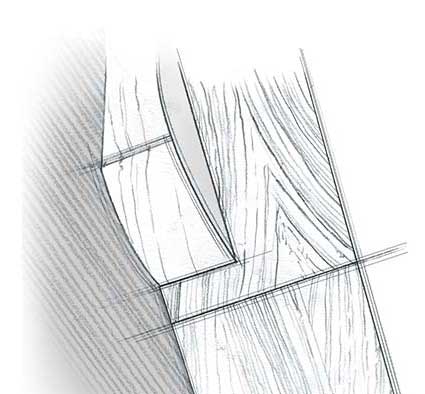

9. Solid Wood Dovetail Support

Thick, solid wood cross supports utilize dovetail joinery to the table frame at each slate joint. With this construction, the cross supports become an integral part of the table frame, and support the slate joints as though the slate was one piece achieving superior performance.

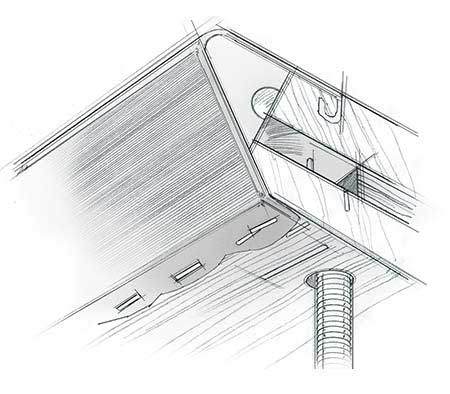

10. Rock-solid and Ready to Install

Brunswick tables come ready-to-assemble and utilize machine nut and bolt construction and galvanized steel leg plates to achieve a rock-solid fine furniture product that is easy to deliver and install in homes.

11. Kiln-dried, Stained, and Sealed

Brunswick Billiard’s goal is to provide our customers with a product that will last a lifetime. All solid wood materials are kiln-dried to a 6 – 8% moisture level, then stained and sealed to keep moisture out. A multi-step, durable, fine furniture finish completes the look of each Brunswick product, making it worthy to be passed on from generation to generation.

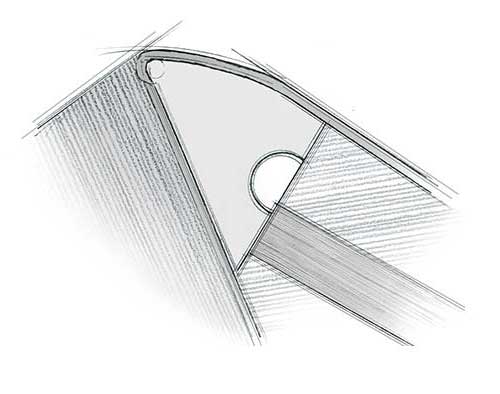

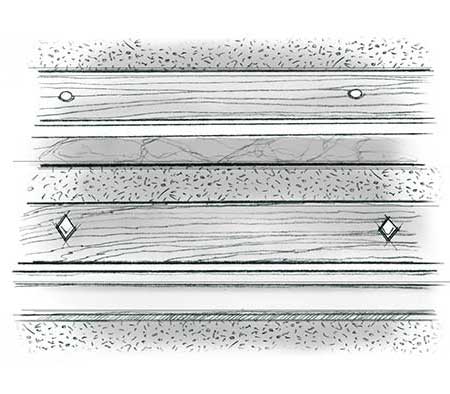

12. Brunswick Certified Slate

Brunswick slate must pass rigid quality requirements before it receives a “Brunswick Certified” sticker. Brunswick slate is diamond- honed, precision-machined and leveled to within ten-thousandths of an inch. Brunswick slate is cured for an extended period of time to assure stability, and is checked for flatness on the top and bottom at least four times through the machining and curing process to a standard twice exceeding BCA specifications on an end- to-end basis. Every set of Brunswick slate is quality inspected and certified, and will provide a lifetime of playability.